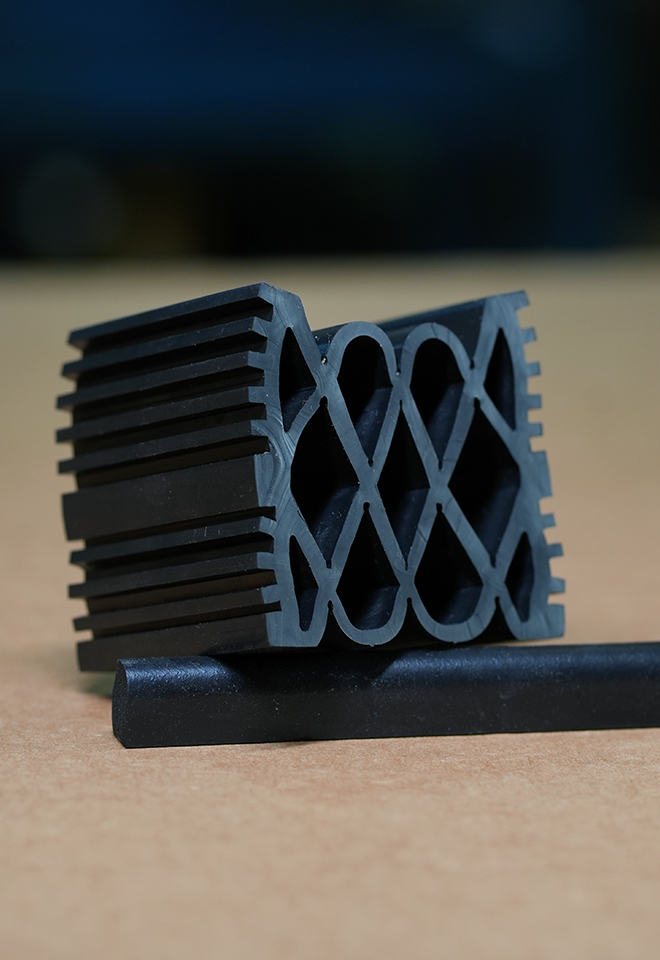

EPDM and silicone vulcanized frames and corners are durable components known for their sealing capabilities. EPDM offers weather and chemical resistance, while silicone provides high-temperature resistance and flexibility. Both materials ensure reliable sealing in various applications, withstanding harsh conditions and offering long-lasting performance.

Please complete the short contact form below, or alternatively fill out the full Damper Quote Request form with your specific requirements.